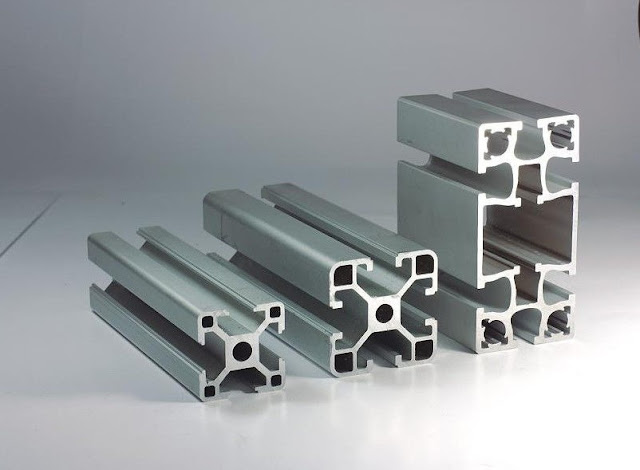

Aluminum Extrusion Is A Manufacturing Process Used To Create Complex Shapes And Profiles

|

| Aluminum Extrusion |

Extrusion of aluminium is a manufacturing

method that produces intricate forms and profiles by forcing heated aluminum

through a shaped die. It is a versatile and widely used technique in various

industries, including construction, automotive, aerospace, and consumer goods.

This process offers numerous advantages, such as cost-effectiveness,

flexibility in design, and lightweight yet durable end products. The

process of Aluminum Extrusion begins

with the selection of high-quality aluminum billets, which are heated to a

specific temperature. The heated billet is then loaded into a press and pushed

through a specially designed die. The die determines the final shape and

cross-sectional profile of the extruded aluminum product. The force applied to

the billet is typically hydraulic, which ensures precise control over the

extrusion process.

One of the key benefits of Aluminum

Extrusion is its cost-effectiveness. Aluminum is abundant,

lightweight, and easy to work with, making it an economical choice for

manufacturing. The extrusion process allows for the production of large

quantities of identical parts quickly and efficiently, reducing material waste

and minimizing production costs. Another advantage of Extrusion of

aluminium is its versatility in design. The flexibility of the extrusion

process enables the creation of complex shapes and profiles that would be

difficult or costly to achieve using other manufacturing methods. The die can

be customized to produce a wide range of profiles, including solid rods, hollow

tubes, channels, angles, and intricate cross-sections. This adaptability makes Extrusion

of aluminium ideal for applications that require unique designs and precise

specifications.

Aluminum

Extrusion offer excellent strength-to-weight ratio properties.

Aluminum is inherently lightweight, which is advantageous for applications

where weight reduction is critical, such as in the automotive and aerospace

industries. Despite its lightweight nature, aluminum exhibits remarkable

strength and durability, making it suitable for various structural

applications. Furthermore, Extrusion of aluminium offer exceptional

corrosion resistance. Aluminum naturally forms a protective oxide layer when

exposed to the atmosphere, preventing further oxidation and corrosion. This

characteristic makes extruded aluminum products highly durable and suitable for

outdoor applications, where they are exposed to harsh environmental conditions.

Additionally, Aluminum Extrusion allows for easy integration of additional features into the extruded profiles. Through secondary operations like cutting, drilling, milling, and surface finishing, the extruded parts can be further customized to meet specific requirements. These post-extrusion processes provide flexibility in adding functional elements, such as holes for assembly, slots for interlocking, or aesthetic finishes like anodizing or powder coating. Extrusion of aluminium is a versatile and cost-effective manufacturing process that enables the creation of complex shapes and profiles with excellent strength-to-weight ratio and corrosion resistance.

Comments

Post a Comment