3D ICs Are Advanced Semiconductor Devices That Offer Improvements In Performance, Power Efficiency

|

| 3D ICs |

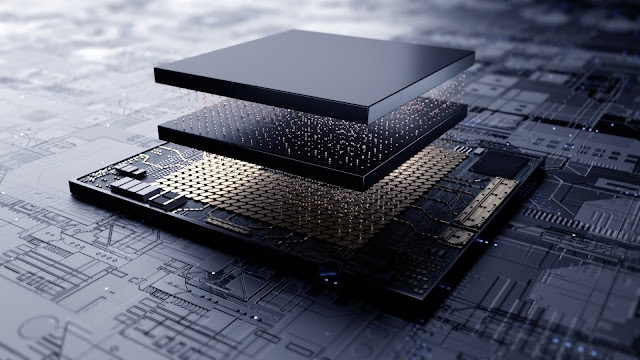

3D ICs (Three-Dimensional Integrated Circuits) are

advanced semiconductor devices that offer significant improvements in

performance, power efficiency, and form factor compared to traditional

two-dimensional integrated circuits. They are designed to overcome the

limitations of Moore's Law, which predicts the continuous miniaturization of

transistors on a single chip. By vertically stacking multiple layers of

circuitry, Three-Dimensional Integrated Circuits enable increased integration

of components, reducing interconnect lengths and improving overall system

performance. One of the key advantages of Three-Dimensional Integrated Circuits

is their ability to achieve higher transistor densities. Instead of spreading

transistors across a larger area, 3D IC stack them vertically, effectively

increasing the number of transistors per unit area. This dense integration

leads to faster and more powerful circuits, as signals need to travel shorter

distances, reducing latency and improving overall system speed.

According To Coherent Market

Insights, The 3D ICs Market Was Valued At

US$ 7,521.4 Mn In 2019 And Is Anticipated To Grow By 22.5% CAGR To US$ 38,252.9

Mn By 2027.

Furthermore,

3D ICs facilitate heterogeneous

integration, allowing different technologies and functionalities to be combined

in a single package. This enables the integration of processors, memory,

sensors, and other components on the same chip, leading to more efficient and compact

systems. For example, a 3D IC could incorporate a high-performance processor,

memory modules, and specialized accelerators, all interconnected within a small

footprint. Another advantage of 3D IC is their improved power efficiency. By

reducing interconnect lengths and parasitic capacitance, 3D IC can minimize

power consumption and improve signal integrity. The shorter interconnects also

help reduce signal delays and increase data transfer rates. This enhanced power

efficiency is crucial in modern electronic devices that demand both high

performance and long battery life.

The

manufacturing process for 3D ICs involves techniques such as through-silicon vias

(TSVs) and wafer bonding. TSVs are vertical interconnects that pass through the

silicon substrate, enabling electrical connections between different layers of

the 3D IC. Wafer bonding techniques are used to stack and bond the individual

layers together, ensuring proper alignment and electrical connectivity. Despite

their numerous advantages, there are also challenges associated with 3D IC. The

thermal management of stacked layers can be more complex compared to

traditional ICs due to heat dissipation issues. Additionally, the manufacturing

process for 3D IC is more intricate and expensive, requiring precise alignment

and control during the stacking and bonding steps. Nevertheless, the potential

benefits of 3D ICs have attracted

significant research and development efforts. They are being explored for

various applications, including high-performance computing, mobile devices,

networking equipment, and automotive electronics. The improved performance,

power efficiency, and compactness offered by 3D IC make them an attractive

option for addressing the ever-increasing demands of modern electronic systems.

Comments

Post a Comment